Products

Ductile iron pipes offer a combination of strength, durability, and reliability that make them the preferred choice for various applications where robust performance is essential. There are several compelling reasons to choose ductile iron pipe: Superior Mechanical Properties, Economic Efficiency, Resilience, Robustness during Handling and Installation, and Temperature Resistance

Ductile iron pipes are utilized in trenchless applications for water and sewer lines. With internal and external coatings of durable materials such as cement, asphalt, paint, or polyethylene encasement, they demonstrate longevity exceeding 100 years.

- Home

- Products

Product Overview

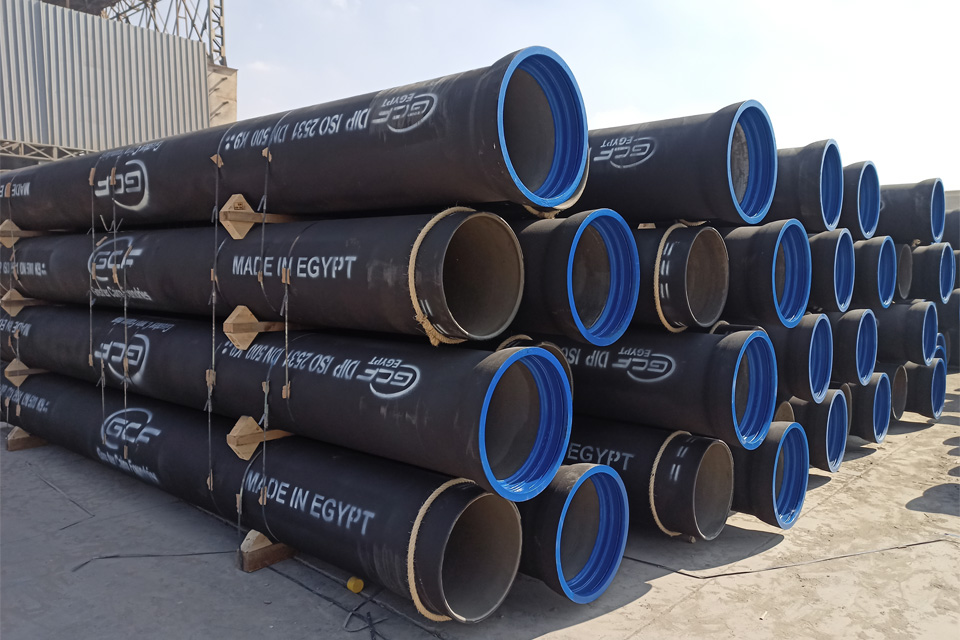

Product: Ductile iron pipes

Type: The T-type Joint Pipe (Push-on)

Standard: ISO2531, EN545, EN598

Sizes: DN80-1200

Thickness: K9, K10, C Class

Length: 6 m

Applications: Water supply project, drainage, drinking water sewage water, irrigation, water pipeline.

Certificates: ISO9001, ISO14001, ISO45001, SGS, WRAS

Internal Coating:

a) Portland cement mortar lining

b) Sulphate Resistant cement mortar lining

c) High-Aluminum cement mortar lining

d) Black bitumen painting

External Coating:

a) Zinc + bitumen painting

b) Zinc-aluminum alloy + liquid epoxy painting

Standards:

• ISO 2531 (Ductile iron pipes, fittings, accessories and their joints for water applications)

• EN 545 (Ductile iron pipes, fittings, accessories and their joints for water pipelines. Requirements and test methods)

• ISO 7186 (Ductile iron products for sewerage applications)

• EN 598 (Ductile iron pipes, fittings, accessories and their joints for sewerage applications. Requirements and test methods)

• ISO 4179 (Ductile iron pipes and fittings for pressure and non-pressure pipelines – Cement mortar lining)

• ISO 8179 (Ductile iron pipes – External zinc coating – Part 2: Zinc rich paint with finishing layer)

• ISO 4633 (Rubber seals – Joint rings for water supply, drainage and sewerage pipelines -Specification for materials)

Quality Control:

Mechanical Properties Testing, Chemical Component Analysis, Hydraulic pressure, Cement, bitumen, zinc testing and dimensional check

Rubber Gasket:

GCP’s Rubber gaskets are made from vulcanized synthetic rubber with a soft rubber bulb and harder heel joined in a strong, vulcanized bond.

EPDM / SBR / NBR (EN681-1, ISO4633)

Packing:

Pipes which diameter under 300mm are bundled with steel belts, Others in bulk

Storage and transportation

Ductile iron pipes are strong enough to resist damage during road transportation or handling by cranes or forklifts in seaports and at site.

How Can You Benefit From GCP’s Services?

“DI pipes are commonly used in infrastructure projects due to their durability, corrosion resistance, and ability to withstand high pressure, ensuring reliable water and wastewater management systems.”

Quality control

Quality control in ductile iron pipe casting includes rigorous testing, process refinement, and adherence to ISO 9001:2015 standards for quality management.

Heat treatment

In the heat treatment section, the cast pipes undergo annealing in a specialized furnace to enhance their strength and ductility

Ductile Iron pipes

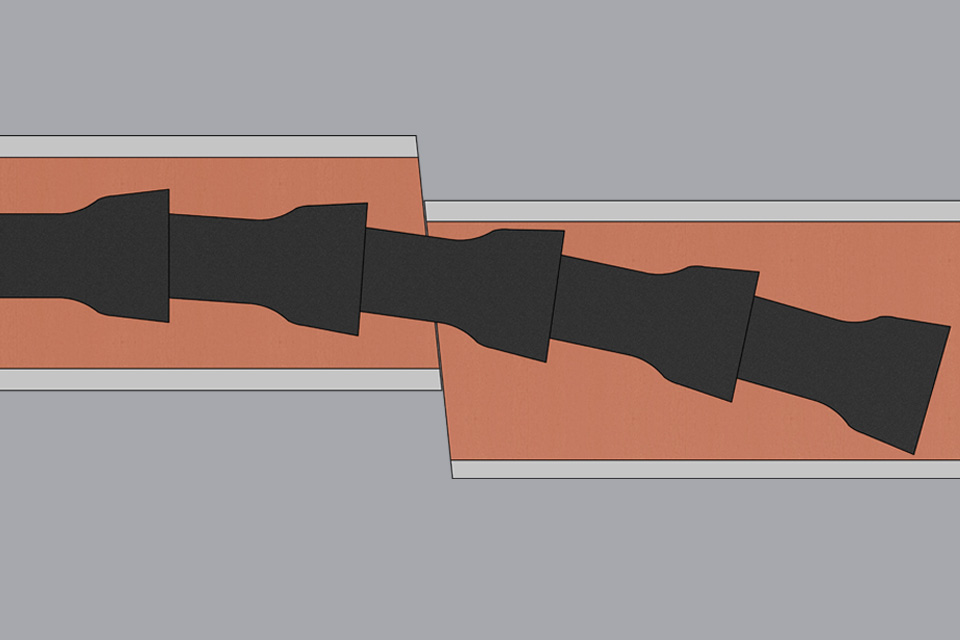

Ductile iron pipes, manufactured through the centrifugal casting technique, are nodular cast iron pipes commonly employed in drinking water systems

Why Ductile Cast Iron?

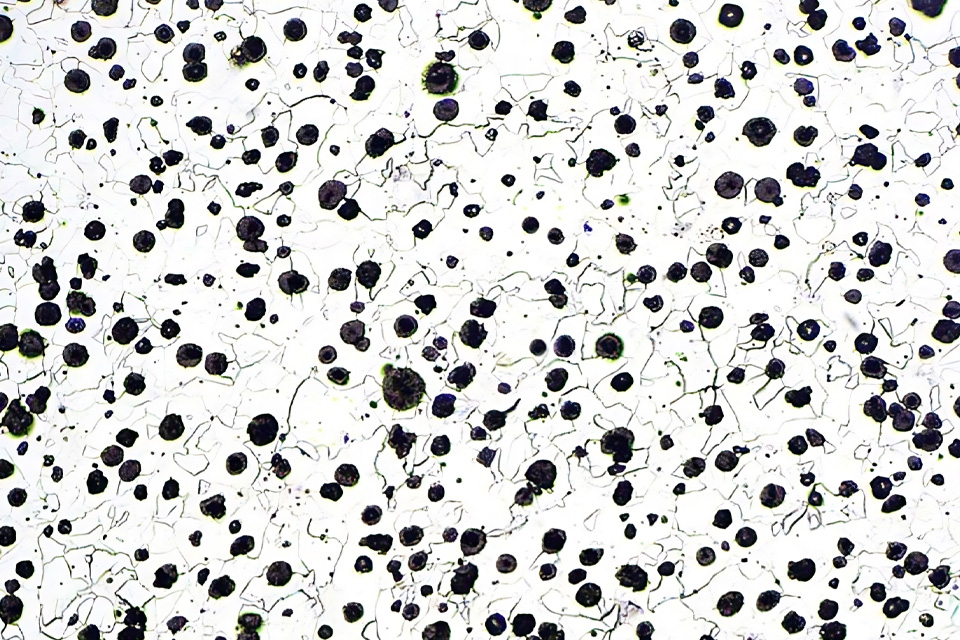

Ductile cast iron is a material composed of plastically malleable iron-carbon, where carbon is primarily present in the form of spheroidal graphite. Unlike grey cast iron, the graphite particles in ductile cast iron are spherical in shape. The term “ductile” originates from the Latin word “ducere,” meaning pliable, and denotes its malleability. In structural analysis, ductile cast iron pipes are considered to possess flexible properties due to their pliability.

The introduction of magnesium into the molten metal alloy facilitates the formation of graphite spheres instead of flakes. This transformation eliminates the brittleness associated with grey cast iron, resulting in the desired characteristics of ductile iron. Ductile iron exhibits a combination of favorable mechanical properties found in steel (such as ductility, strength, and toughness) along with the corrosion resistance typical of cast iron.

Ductile iron pipes offer a combination of strength, durability, and reliability that make them the preferred choice for various applications where robust performance is essential. There are several compelling reasons to choose ductile iron pipe:

1. Superior Mechanical Properties: Ductile iron offers a unique blend of mechanical properties similar to steel while maintaining better corrosion resistance than traditional cast iron pipes.

2. Economic Efficiency: Compared to alternative piping materials such as plastics and concretes, ductile iron pipes provide the most cost-effective solution over the long term.

3. Resilience: Ductile iron pipes are engineered to withstand the harshest operational and environmental conditions, ensuring reliable performance even in challenging situations.

4. Robustness during Handling and Installation: Ductile iron is the preferred choice for pipe material during handling and installation due to its durability and ease of installation. It can withstand demanding operating conditions such as surge pressure and water hammer.

5. Temperature Resistance: Ductile iron pipes exhibit exceptional resistance to extreme high and low temperatures without experiencing brittleness.

Why Push-On Joints?

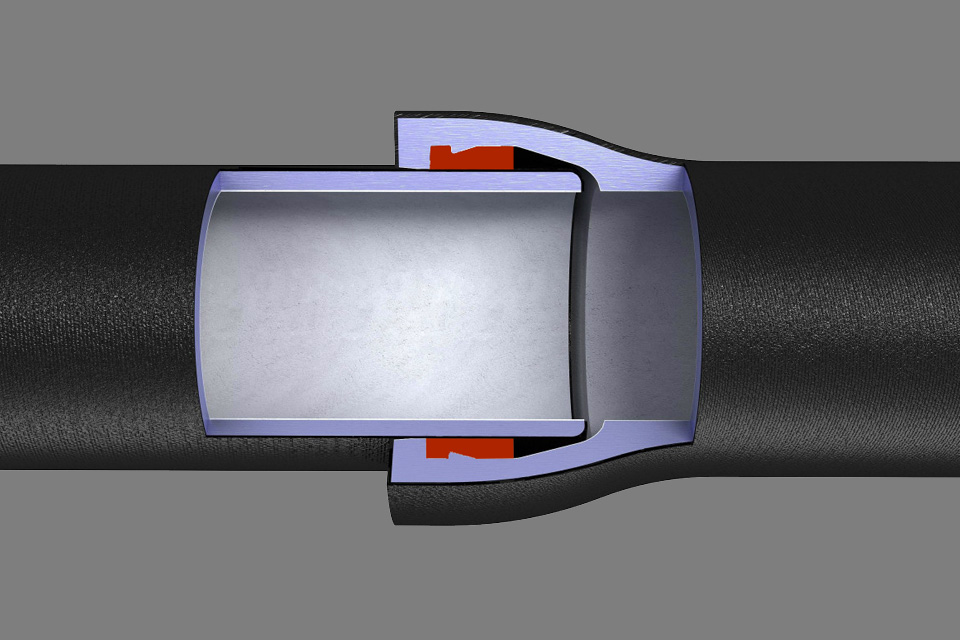

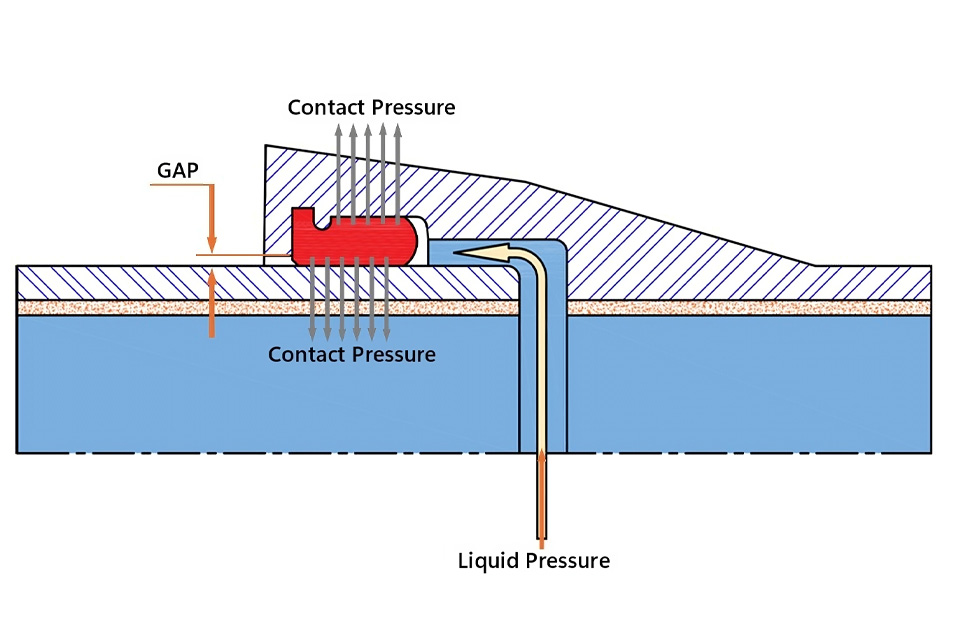

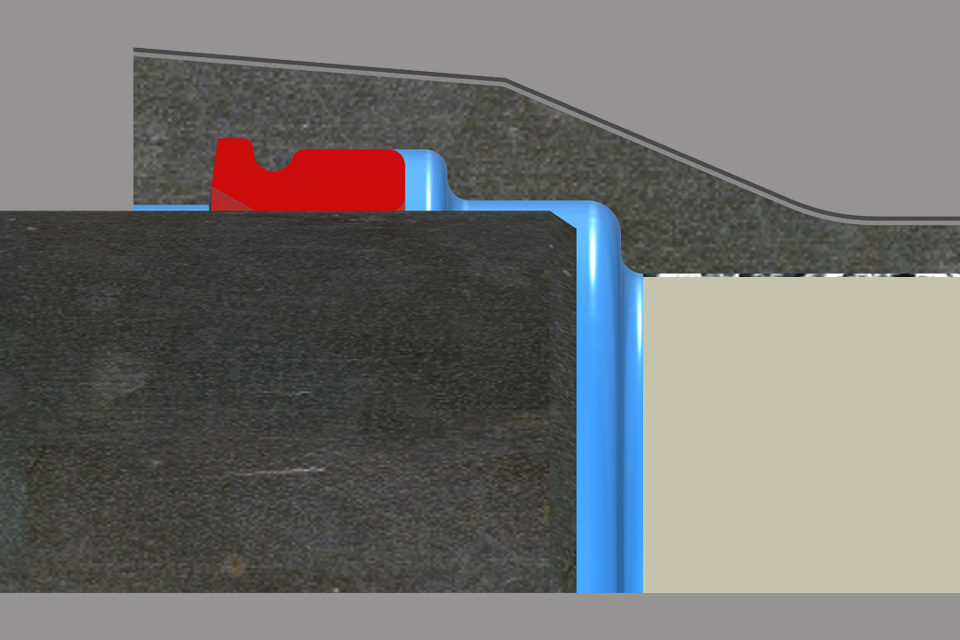

- For underground applications, the “push-on joint” is the most often used, fastest, and most straightforward joint for Ductile Iron Pipe and fittings. At the socket end of the pipe, this joint is made up of a single rubber gasket inserted into a groove inside the socket. The chamfered end of the pipe is pushed past the gasket, compressing it and creating a reliable and pressure-tight seal, after the joint has been lubricated in accordance with the installation instructions.

- The Push-on Joints design for ductile iron pipes socket (T-Tyton Type) allows for significant joint deflection, ensuring the pipeline can withstand ground settlement, as detailed in the accompanying table. Additionally, the T-Tyton joint design enhances leak tightness by leveraging the water pressure within the pipeline.

- Push-in joints serve as axially movable joints capable of withstanding high loads. They maintain leak tightness even when pipes are misaligned or angularly deflected to their maximum extent.

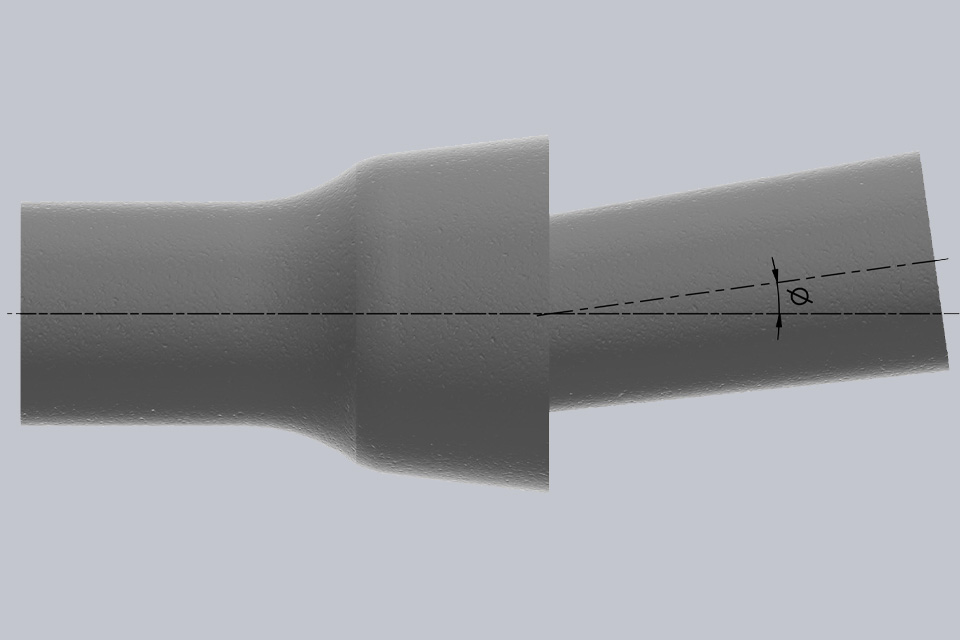

Angular Deflection of DI Pipes (Push-in Joints)

GCP socket joints offer the advantage of angular deflection. This feature not only facilitates installation and accommodates ground movements, but also enables the negotiation of large-radius bends without the need for additional fittings. Additionally, it allows for a degree of route adjustment. Spigot joints permit angular deflection which gives the following advantages:

- Accommodation of ground movements

- Allowing adjustment while installation

- Reducing the number of bends required

Maximum Angular deflection Ø (Tyton T-Joint)

- DN80 – DN300 = 5°

- DN350 – DN450 = 4°

- DN500 – DN1000 = 3°

- DN1200 = 1.5°

DI Pipes Layer Structure and Wall Thickness

DI Pipe base metal:

- The mechanical properties of ductile iron are markedly superior to those of grey iron and more comparable to the properties of steel pipes. The much-improved properties were recognized to be of particular benefit in the centrifugal pipe industry and as such the majority of potable water projects, worldwide, use ductile iron.

Protective coating consists of

A- Zinc coating Layer:

Protective Coating shall be applied to all pipes in accordance with ISO 81791- and with EN545. The coating shall comprise either one of the following:

- Metallic Zinc Spray with a mass of 130g/m2 (ISO 8179) or 200g/m2 (EN 545)

- Zinc Aluminum alloy (85% Zinc – 15% Al) with a mass of 400g/m2

B- Bitumen/Epoxy coating layer:

The metallic zinc layer is followed by a bitumen topcoat with an average thickness of no less than 70 microns and a minimum of 50 microns at any given point. For Zinc-Aluminum alloy, the top layer typically consists of an epoxy coating, which can be red, blue, or any other color appropriate for the application.

Cement lining:

DI Pipes are typically lined with cement mortar lining (CML) as per ISO 4179. There are different cement mortar linings provided in DI Pipes. The type of lining depends on the aggressiveness of raw and potable water. Factors characterizing the

aggressiveness of raw and potable water are: pH, Sulfates, Magnesium, Ammonium, and Aggressive CO2

Rubber Gasket:

EPDM / SBR / NBR (EN681-1, ISO4633)

Epoxy coating Socket detail :

Excellent corrosion resistance, excellent adhesion and toughness, Color: Blue, and 200-250 microns nominal thickness.

Wall thickness:

K class and C-Class as per ISO 2531 and EN 545